ROTATING SELF CLEANING DEJUICER

To be placed under the fermentation tanks to separate solids during the racking phase.

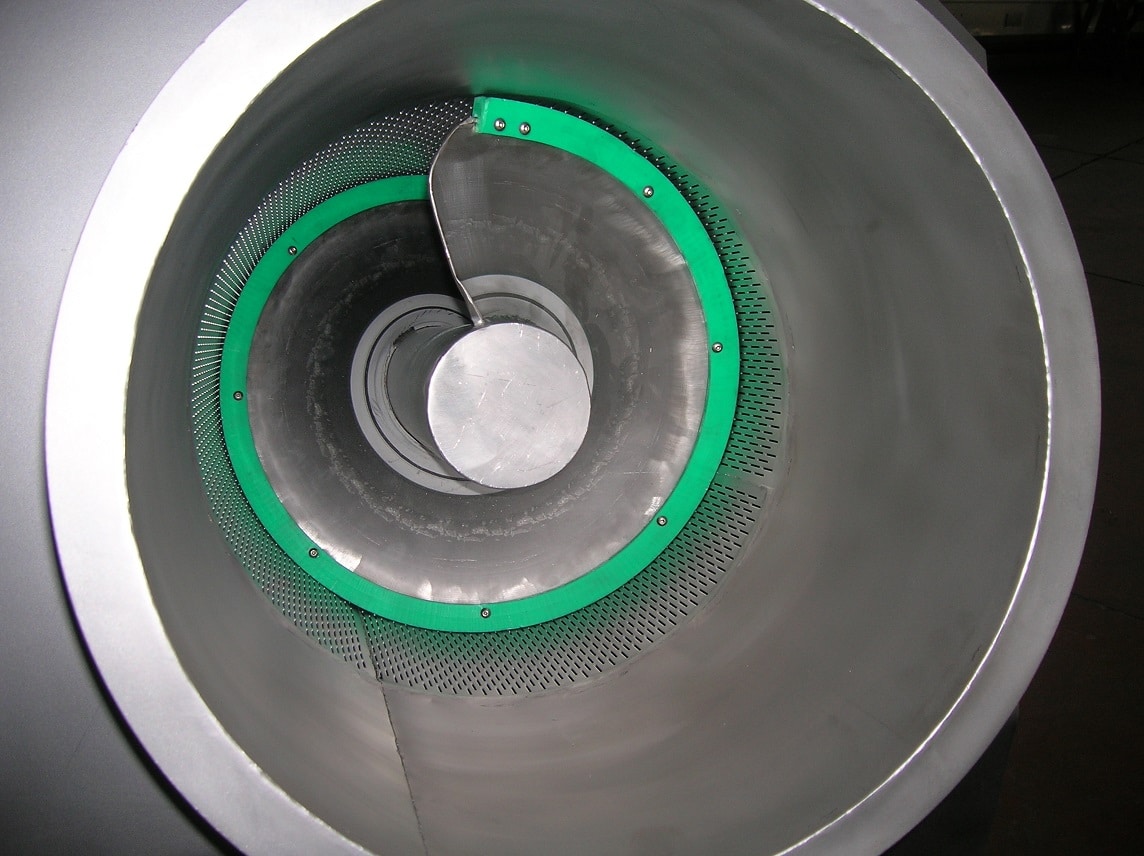

Entirely made in AISI 304 stainless steel and composed of an external case in folded sheet metal which forms the support frame.

The case supports a perforated cage in AISI 304 stainless steel, built with cut sheet metal.

Inside the cage there is a Ø 400 screw entirely built in AISI 304, equipped with a polyzene support wrapped around the screw.

The cage and the auger can be disassembled to facilitate cleaning operations.

The Dejuicer is equipped with a gear motor complete with speed variator, wheels for moving, and a porthole at the end of the cage.

PRODUCTIVITY UP TO 60 TONS/H